Introduction

The core system, the Manufacturing Execution System (MES), had become outdated, relying on technologies that were no longer supported. The limitations of the old system included the need to run the application in a special browser mode and the lack of support for mobile devices like tablets. Additionally, it was crucial to adopt the latest data security and encryption standards. To ensure the system’s future scalability and security, a migration to the latest .NET technology stack was necessary.

Project Overview

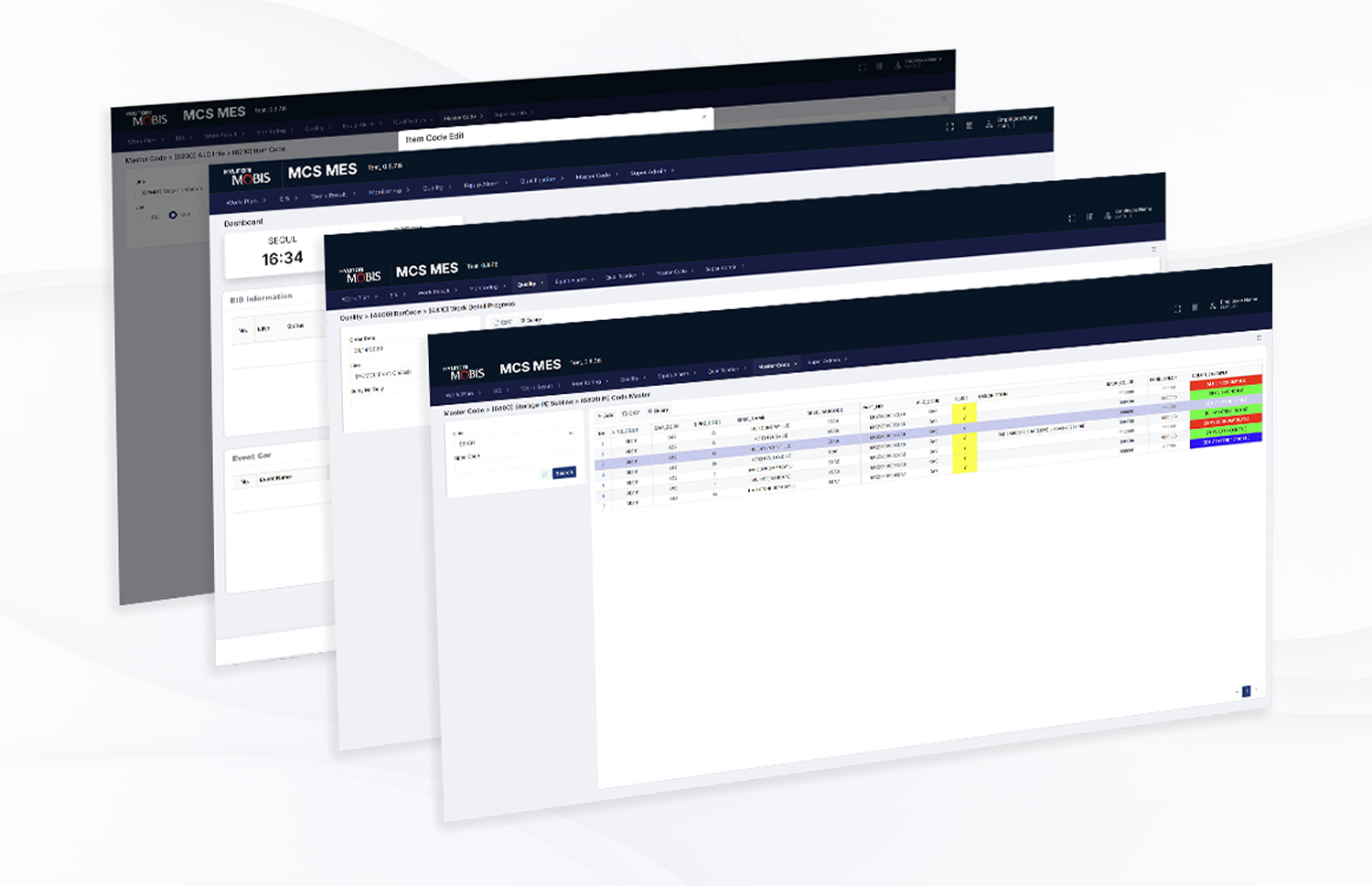

Given the critical role the MES system played in the factory’s operations, the migration needed to be handled with great care and precision. The new system was introduced incrementally, with both the legacy and updated systems running in parallel during the testing phase. Although the legacy system would only be used when absolutely necessary, backward compatibility was a key requirement. This ensured that page configurations could be used seamlessly, regardless of which system they originated from, as both systems relied on the same data source.

Challenges and solution

One major challenge was creating a fully functional development environment. The MES system is a complex platform that relies on multiple data sources, some of which could not be provided for testing, while others contained faulty data. This required constant validation against the production version to ensure accuracy. Additionally, the development workflow was impacted by strict security protocols and frequent changes in permission policies within Mobis’s internal infrastructure.

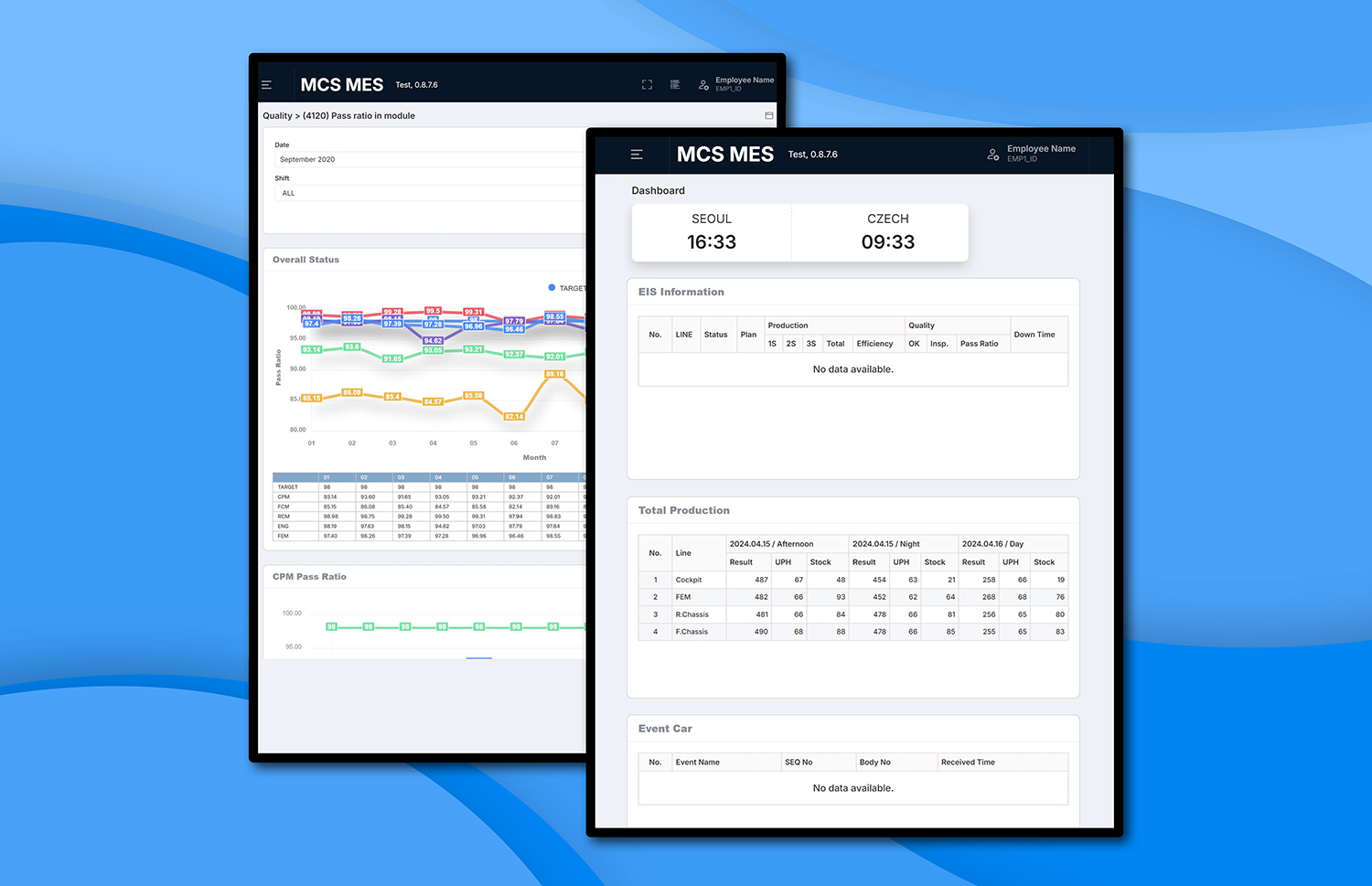

Optimizing deployment to ensure a seamless transition without extensive retraining for employees was also essential. This demanded a user-friendly interface and rapid deployment. Given the complexity of certain views within the system, supporting tablet displays was another major challenge. The new functionality allows users to work efficiently outside of their workstations, enabling them to respond quickly to requests while on the go. Close cooperation with the Mobis IT department was vital to address evolving requirements and ensure smooth integration with the existing infrastructure.

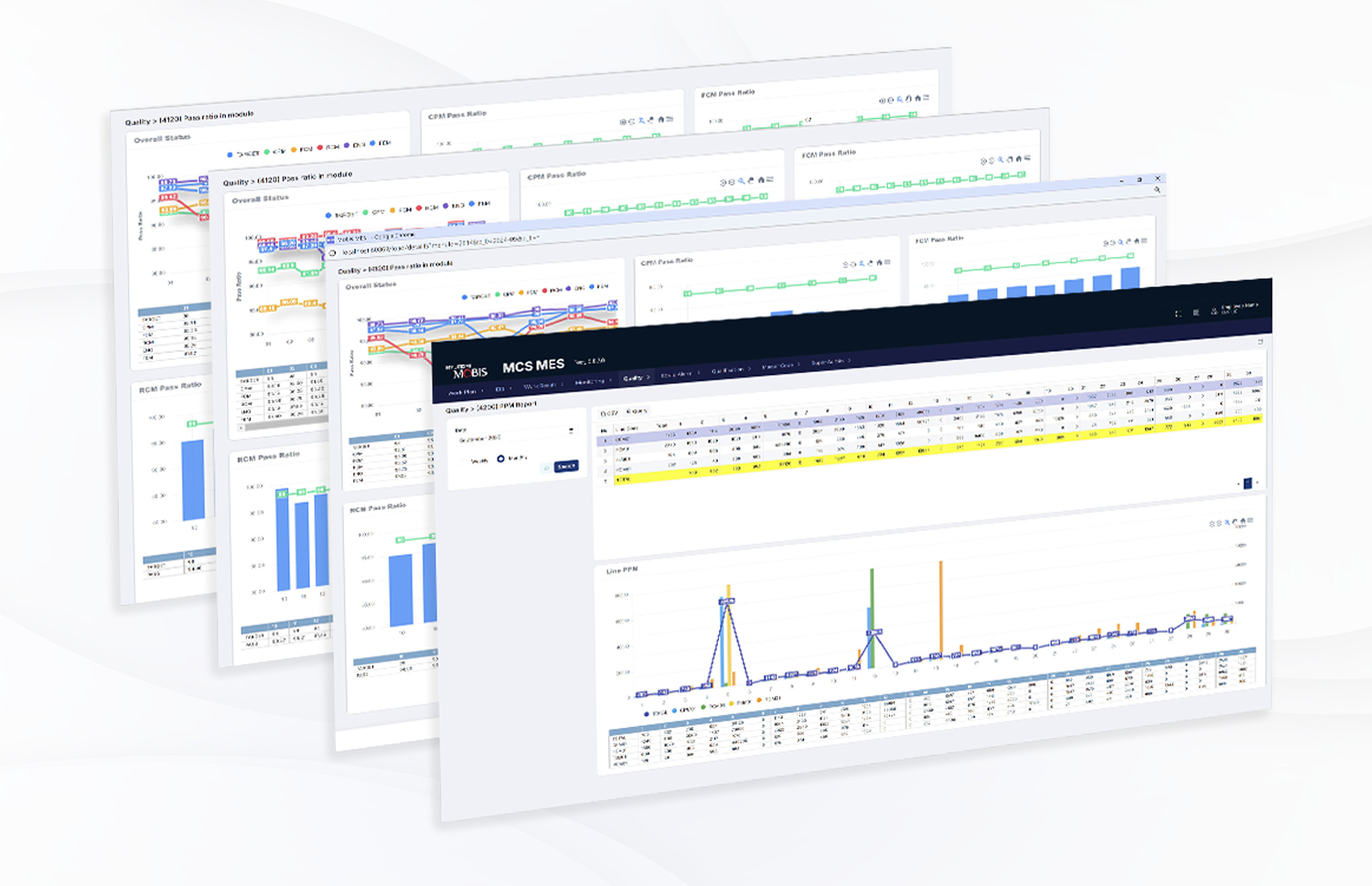

Despite the challenges, our experienced team successfully delivered a robust and secure application. The MES system is structured into three main components: a Page Configurator that defines individual pages, a Renderer that generates pages ranging from simple layouts to complex, interconnected modules, and an Administrative Module that controls user access and manages the visibility of pages based on permissions. The project also involved migrating custom pages, which primarily display data visually using charts.

Results and Impact

The system is now live in production, with plans for further enhancements and continued development. The successful migration laid the foundation for easier maintenance and future feature additions. We continue to work closely with the Mobis IT team to enhance the app’s capabilities, ensuring it remains a valuable asset for the factory. Hyundai Mobis now enjoys faster and more reliable app performance, enhanced security features, improved UI and overall user experience, long-term support and future-proofing, and a fully responsive design that supports modern browsers and tablet views.

Through this project, Hyundai Mobis has not only modernized its critical system but also ensured a scalable and secure solution, aligning with the latest technological standards.

-

Date

Q4/2023 - Q1/2024

-

Client Name

Mobis Automotive Czech s.r.o.

-

Technologies

.NET 8.0, C#, ASP.NET Core, MVC, Dapper, .NET SQL Server